Liquid beverage processing plants: the use process and precautions of beverage machinery

The beverage processing technology mainly depends on three factors, namely the pH value of the beverage, the volume of the beverage, and the packaging form. The pH value of the product determines the choice of process in the entire industry. According to the difference in pH value, beverages can be classified according to the processing technology, and this classification is consistent with the description of the US Food and Drug Administration to classify beverages based on acidity. Beverages with a pH below 4.6 are called high-acid beverages, and those with a pH above 4.6 are called low-acid beverages. In general, the standard heating temperature for high-acid beverages is 180°F to 200°F, and the standard heating temperature for low-acid beverages is 235°F to 280°F. Acidity is very important for beverages, because acidity creates an environment that is not conducive to the growth of microorganisms.

Additives can also create an environment for beverages from multiple angles to inhibit the activity of microorganisms, but they may also increase the activity of microorganisms. Nutrient sources, carbonic acid and preservatives all affect the microbial activity in beverages. As mentioned earlier, acid or beverage acidity is also one of the factors that affect the beverage production environment.

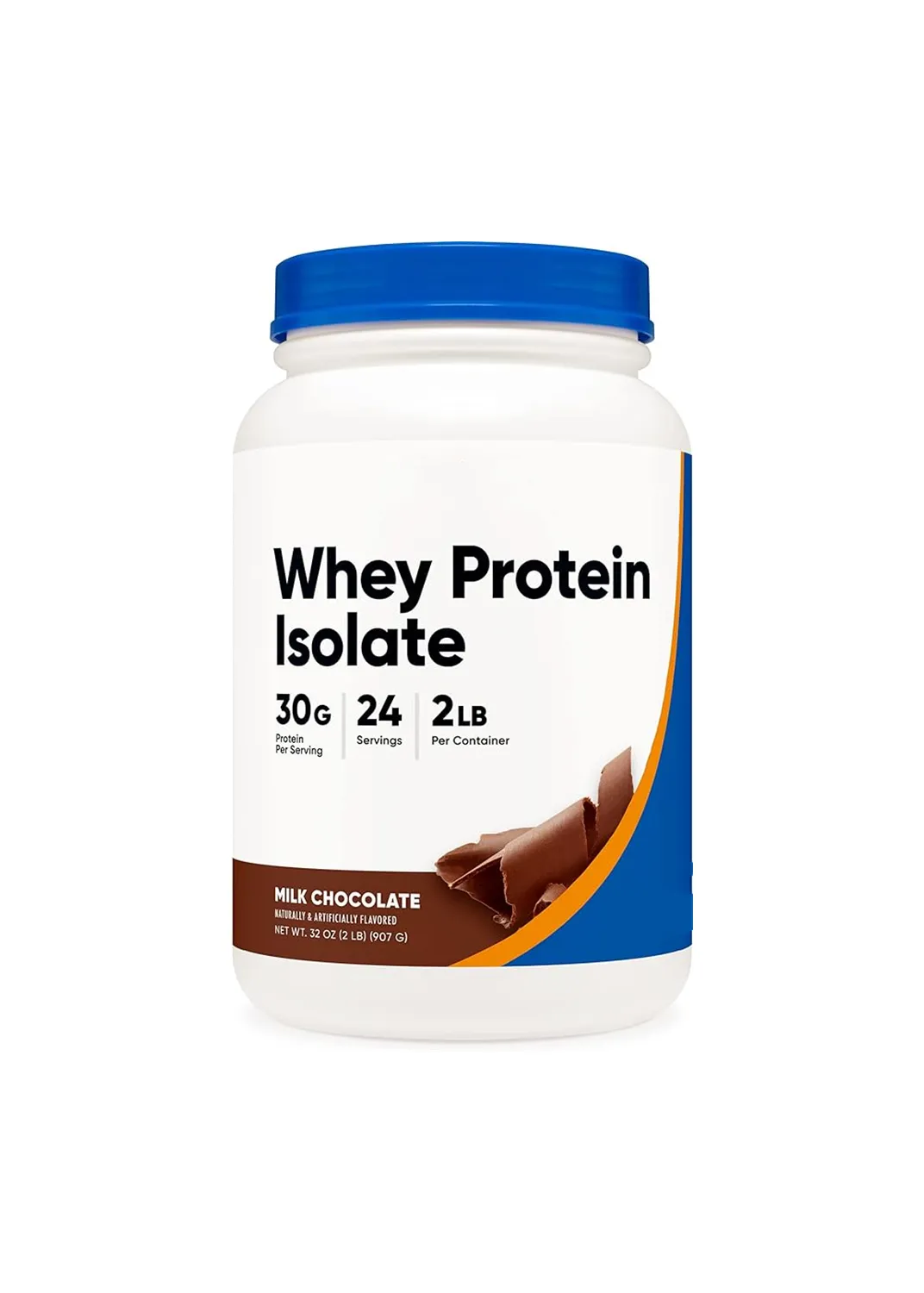

Nutrients usually help the growth of microorganisms. Vitamins, proteins, amino acids, water, milk, cheese, honey, meat extracts, tea, coffee, fruit juice, chewing gum, natural and artificial sweeteners, coloring agents are all nutrients suitable for biological growth. The above-mentioned nutritional components are also key factors for selecting a suitable processing technology when considering the needs of beverage processing.

Whether it is aseptic filling, cold filling, hot filling, retort or tunnel pasteurization, the pH value, additives and packaging of the beverage must be considered. Each method has a different product pH. In the aseptic filling process of the present invention, the pH value is used for separation. The aseptic process of the present invention can be used for both high-acid beverages and low-acid products.

In the aseptic filling process, whether low-acid or high-acid beverages are used, a suitable sterilization temperature can be used. Different from other filling processes, aseptic filling and packaging are all sterilized by hydrogen peroxide or peracetic acid. After pasteurization, the product is cooled and then filled in an aseptic environment. This process parameter makes the aseptic process the most commonly used process in beverage production. However, the processing cost is also the highest.

The second is cold filling, which is suitable for high-acid beverages. During the cold filling process, the concentrated syrup is mixed with water in a certain proportion, and then enters the carbonation furnace. Some cold-filled beverages contain preservatives. This is called "cold filling" because the temperature of the beverage when it enters the packaging is low, and low temperature can help dissolve carbon dioxide in the beverage. Acidity, carbonic acid, and in some cases added preservatives, all of which help improve the overall safety of the beverage. Beverage foundry

Based on the main factors and the characteristics of the beverage, choose the suitable processing technology to meet the requirements of different processing technology for the beverage. The beverage design and product packaging should also be considered when choosing beverages, so as to ensure the safety of beverage products and meet or exceed consumer requirements for beverage quality.